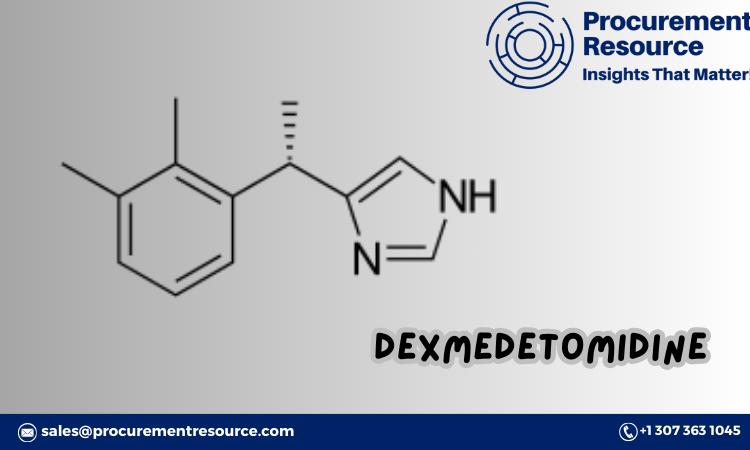

Comprehensive Dexmedetomidine Production Overview: Industrial Insights and Cost Dynamics

Dexmedetomidine is a highly selective alpha-2 adrenergic receptor agonist widely used in medical settings for its sedative and analgesic properties. With growing demand from hospitals and surgical centers, understanding the intricacies of its production cost is critical for both manufacturers and stakeholders. By examining its cost model, pre-feasibility studies, industrial trends, labor charges, utilities, logistics, and supply chain considerations, one gains a clearer perspective on the financial and operational factors shaping this essential pharmaceutical product.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/dexmedetomidine/request-sample

Unpacking the Dexmedetomidine Production Cost Structure

The cost structure of dexmedetomidine production is multi-faceted, encompassing several stages from raw material procurement to final product distribution. Some of the primary cost factors include:

-

Raw Material Costs:

Dexmedetomidine production relies on high-purity starting materials. The selection and quality of these materials directly impact the overall cost. Price fluctuations in the global market, driven by factors such as supply constraints or changing regulations, can significantly alter production economics. -

Labor and Overhead Expenses:

Labor costs are a substantial portion of the production budget. Skilled personnel are needed to oversee synthesis, purification, and quality assurance processes. In addition, overhead expenses—such as facility maintenance, compliance adherence, and administrative support—contribute to the total cost. -

Utility and Energy Usage:

The synthesis and purification of dexmedetomidine require precise temperature control, vacuum systems, and specialized reactors, all of which consume considerable energy. Utilities such as electricity, water, and process gases add to the cumulative production expense. -

Logistics and Supply Chain Management:

Effective logistics is vital for both inbound and outbound supply chains. The sourcing of raw materials often involves international suppliers, adding transportation and customs costs. On the outbound side, timely distribution to hospitals, pharmacies, and other medical institutions ensures a steady revenue stream but also incurs logistical charges.

Pre-Feasibility Studies: A Key Component in Production Planning

Pre-feasibility studies play a pivotal role in the planning phase of dexmedetomidine production. These studies involve comprehensive market analysis, financial modeling, and risk assessment. By estimating potential revenues, identifying key cost drivers, and mapping out production timelines, manufacturers can determine the viability of their projects before committing significant resources. Pre-feasibility analyses also highlight regulatory hurdles and suggest strategies to meet compliance standards efficiently.

Industrial Trends Impacting Dexmedetomidine Production

Several industrial trends are shaping the production landscape for dexmedetomidine. These include:

-

Technological Advancements:

Continuous improvements in chemical synthesis methods, reactor designs, and purification technologies help reduce waste and enhance yields, lowering production costs. -

Market Expansion in Emerging Economies:

As healthcare infrastructure improves in developing countries, demand for advanced sedatives and anesthetics like dexmedetomidine increases. This expansion drives larger production scales and potentially more cost-efficient operations. -

Regulatory Shifts:

Changing regulations, particularly concerning Good Manufacturing Practices (GMP) and environmental standards, influence production costs. Staying ahead of these regulatory changes ensures uninterrupted production and market access.

Labor Charges and Their Influence on Overall Costs

Labor charges remain one of the most variable cost components in dexmedetomidine production. Geographic location plays a significant role: manufacturing facilities in regions with lower wage rates may benefit from reduced direct labor expenses. However, these savings must be balanced against factors like workforce expertise, training requirements, and the need for high-quality standards. Automation is also influencing labor costs, as many companies invest in advanced equipment to minimize human error and increase efficiency.

Utilities and Operational Costs

Utilities form a critical part of the operating expenses. Dexmedetomidine synthesis typically involves multi-step chemical reactions, requiring stable temperature conditions and precise control over reaction environments. These demands lead to high electricity and cooling water consumption. Additionally, waste management processes—essential for compliance with environmental regulations—add to utility expenses. Efficient energy usage and waste reduction strategies can significantly improve cost efficiency.

Logistics and the Role of a Reliable Procurement Resource

The logistics chain is integral to keeping production lines running smoothly. From sourcing raw materials to delivering the final product, reliable and timely logistics ensure that production schedules are met and market demand is fulfilled. This is where having a trusted procurement resource becomes invaluable. A well-established procurement partner can secure consistent raw material supplies, negotiate better pricing terms, and provide market insights that help manufacturers make informed decisions. As a result, leveraging a robust procurement resource can mitigate risks, improve cost predictability, and enhance overall operational stability.

Supply Chain Dynamics and Cost Management

A well-optimized supply chain is the backbone of dexmedetomidine production. Key supply chain considerations include:

-

Vendor Relationships:

Strong relationships with suppliers ensure a steady flow of high-quality raw materials. Long-term contracts and reliable vendors help stabilize costs and reduce the risk of supply disruptions. -

Inventory Management:

Efficient inventory practices prevent overstocking or understocking, balancing the costs of storage against the need for uninterrupted production. -

Distribution Networks:

Setting up an efficient distribution network ensures that finished products reach end-users promptly. Strategically located distribution centers can reduce shipping times and costs, improving overall profitability.

Request a Free Sample

Are you interested in learning more about dexmedetomidine production costs and exploring our detailed cost report? Request a free sample today and gain access to critical insights that can help you make informed decisions.

For more detailed information or to request Free Sample – https://www.procurementresource.com/production-cost-report-store/dexmedetomidine/request-sample

By understanding the intricate details of dexmedetomidine production, businesses can position themselves more effectively in a competitive market, ensure compliance with regulatory standards, and ultimately reduce overall production costs.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA