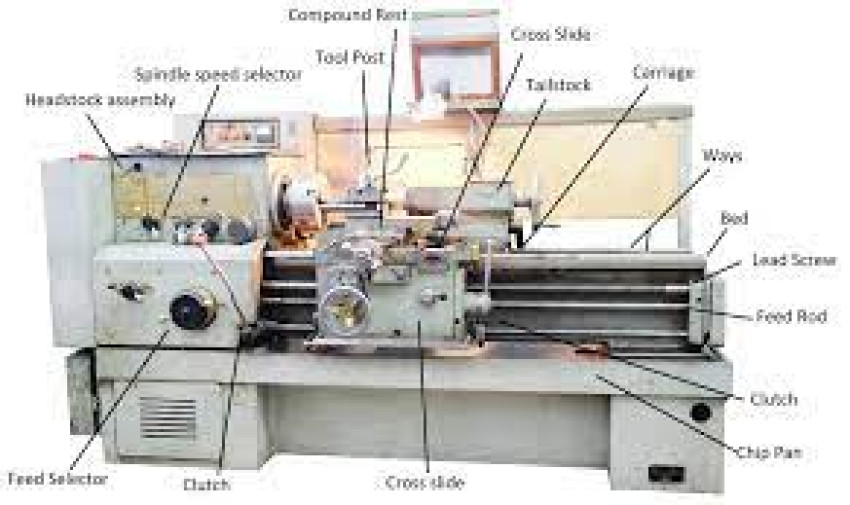

What are the various parts of a lathe machine and their functions

A lathe machine is a versatile tool used in machining operations to shape and turn various materials such as wood, metal, or plastic. It consists of several essential parts, each with its own specific function. In this comprehensive guide, we will explore the main components of a lathe machine and discuss their roles in the machining process.

-

Bed: The bed is the base of the lathe parts and provides support to all other components. It is usually made of cast iron and has precision guide-ways to ensure stability and accuracy during machining.

-

Headstock: The headstock is located at one end of the lathe parts bed and houses the main spindle. It is responsible for providing rotational motion to the workpiece. The spindle is driven by an electric motor and can be adjusted for different speeds.

-

Tailstock: The tailstock is positioned at the opposite end of the lathe parts bed from the headstock. It can be moved along the bed to accommodate different workpiece lengths. The tailstock provides support to the other end of the workpiece and contains a quill that can be extended or retracted to hold the workpiece securely.

-

Carriage: The carriage is the lathe parts that moves along the bed and carries the cutting tool. It consists of several components, including the saddle, cross-slide, and compound rest. The saddle moves along the bed, while the cross-slide moves perpendicular to the bed, allowing for precise positioning of the cutting tool. The compound rest enables the cutting tool to be set at different angles for taper turning.

-

Apron: The apron is attached to the carriage and houses various mechanisms, including the feed and threading mechanisms. It controls the longitudinal and cross feeds, allowing for smooth and accurate movement of the carriage during machining. The apron also contains the gear train responsible for threading operations.

-

Chuck: The chuck is a device used to hold the workpiece securely in place. It is mounted on the spindle and can be of different types, such as three-jaw chuck or four-jaw chuck. The three-jaw chuck is commonly used for holding cylindrical workpieces, while the four-jaw chuck provides greater flexibility for irregularly shaped workpieces.

-

Tool Post: The tool post is attached to the carriage and holds the cutting tool. It allows for quick and easy tool changes, as different tools may be required for different machining operations. The tool post can be manually adjusted for tool height and angle.

-

Cutting Tool: The cutting tool is an essential component of the lathe parts and is used to remove material from the workpiece. It can be made of high-speed steel, carbide, or other materials depending on the material being machined. The cutting tool is securely clamped in the tool post and can be shaped differently to perform various operations such as turning, facing, grooving, or threading.

-

Feed Rod: The feed rod is a threaded rod connected to the carriage. It engages with the gear train in the apron and controls the longitudinal feed of the carriage. By rotating the feed rod, the operator can control the rate at which the cutting tool moves along the workpiece.

-

Lead Screw: The lead screw is another threaded rod connected to the carriage. It is responsible for providing the necessary motion for threading operations. When the lead screw rotates, it engages with the gear train in the apron, causing the carriage to move at a specific pitch, thus creating threads on the workpiece.

-

Steady Rest: The steady rest is an optional attachment used to support long or slender workpieces during machining. It prevents excessive deflection or vibration and ensures greater stability and accuracy. The steady rest consists of adjustable jaws that can be positioned to hold the workpiece firmly in place.

-

Coolant System: Many lathe parts machines are equipped with a coolant system to prevent overheating and improve machining efficiency. The coolant, usually a water-based solution, is directed to the cutting area to reduce friction and carry away chips and debris, keeping the workpiece and cutting tool at optimal temperatures.

Understanding the different parts of a lathe parts machine and their functions is crucial for operating and utilizing this powerful machining tool effectively. By utilizing the various components correctly, machinists can achieve precise and high-quality results in turning and shaping workpieces.