Unraveling the Crystal Clear Market: Ultra High Purity Silicon Carbide

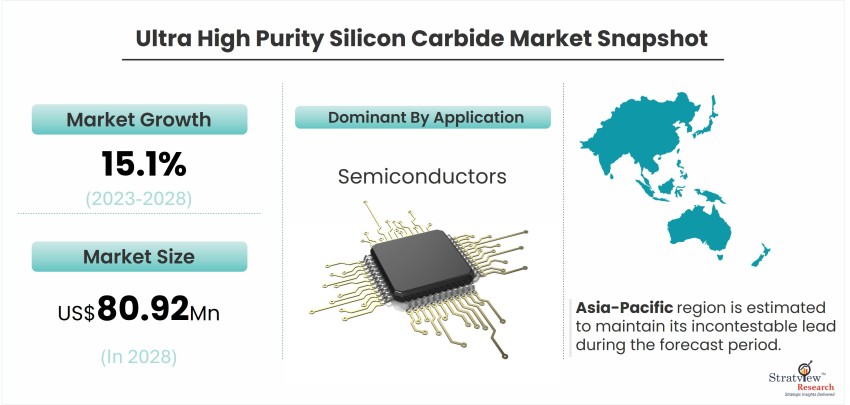

According to Stratview Research, the ultra high purity silicon carbide market was estimated at USD 34.8 million in 2022 and is likely to grow at a CAGR of 15.1% during 2023-2028 to reach USD 80.92 million in 2028.

In the realm of advanced materials, few substances hold the promise of ultra high purity silicon carbide (UHP SiC). Renowned for its exceptional properties and versatility, UHP SiC has been at the forefront of material innovation, pushing the boundaries of what is possible in industries ranging from electronics to aerospace. In this article, we embark on a journey to explore the latest innovations in ultra high purity silicon carbide, uncovering breakthroughs that are redefining material science and opening new horizons for technological advancement.

The Foundation of Ultra High Purity Silicon Carbide

At its core, ultra high purity silicon carbide is a crystalline compound composed of silicon and carbon atoms in a 1:1 ratio. What sets UHP SiC apart is its remarkably low levels of impurities, which are typically measured in parts per million (ppm). This unparalleled purity, combined with its exceptional thermal conductivity, mechanical strength, and chemical resistance, makes UHP SiC a material of choice for a wide range of demanding applications.

Advancements in Material Synthesis

Recent years have seen significant advancements in the synthesis and manufacturing of ultra high purity silicon carbide. Innovations in crystal growth techniques, purification processes, and doping methods have led to the production of UHP SiC with unprecedented levels of purity and uniformity. These advancements have not only expanded the range of applications for UHP SiC but have also enabled the development of new materials with enhanced properties and performance characteristics.

Precision Engineering for Performance

In addition to advancements in material synthesis, precision engineering techniques are playing a crucial role in enhancing the performance and functionality of ultra high purity silicon carbide. Innovations such as nanoscale patterning, surface modification, and defect engineering are enabling the design and fabrication of UHP SiC-based devices with tailored properties and functionalities. These precision-engineered materials are poised to revolutionize industries such as electronics, photonics, and power generation.

Applications Across Industries

The innovations in ultra high purity silicon carbide are transcending traditional boundaries, with applications emerging across a diverse range of industries:

Electronics and Semiconductors: In the electronics industry, UHP SiC is revolutionizing the design and performance of high-power devices, including diodes, transistors, and integrated circuits. Its high thermal conductivity and low power loss characteristics enable the development of more efficient and reliable electronic systems.

Photonics and Optoelectronics: In the field of photonics and optoelectronics, UHP SiC is being used to fabricate advanced optical components such as mirrors, lenses, and waveguides. Its excellent optical properties, combined with its mechanical strength and chemical stability, make it an ideal material for applications requiring precision and durability.

Renewable Energy: In the renewable energy sector, UHP SiC is driving innovation in solar photovoltaics, power electronics, and energy storage systems. Its high temperature stability and resistance to corrosion make it an attractive material for components operating in harsh environments, such as solar panels, inverters, and batteries.

Looking Ahead: The Future of UHP SiC

As we look to the future, the innovations in ultra high purity silicon carbide are poised to unlock new possibilities and reshape the landscape of material science. From enabling the next generation of electronic devices to revolutionizing renewable energy technologies, UHP SiC is poised to play a pivotal role in driving innovation and progress across industries. With continued research and development, the boundaries of what is possible with UHP SiC will continue to expand, ushering in a new era of technological advancement and discovery.

Conclusion

In conclusion, the innovations in ultra high purity silicon carbide are pushing the boundaries of material science and engineering, opening new frontiers for technological innovation and advancement. From precision-engineered devices to cutting-edge applications, UHP SiC is redefining what is possible in industries ranging from electronics to renewable energy. As research and development efforts continue to accelerate, the future of ultra high purity silicon carbide holds promise and potential beyond boundaries, paving the way for a world where innovation knows no limits.