Project Planning Techniques of Marine Insulation Companies

Once or twice, the success of a marine insulation project hinges not only on material quality but also on meticulous planning. Efficient project management ensures timely installation, cost control, and adherence to safety standards, particularly when dealing with marine pipe insulation systems. Experienced marine insulation companies employ a variety of planning techniques to coordinate resources, manage schedules, and reduce operational risks. By integrating strategic oversight with practical execution methods, these companies optimize project outcomes while maintaining high-quality acoustic and thermal insulation performance.

Understanding the Scope of Marine Insulation Projects

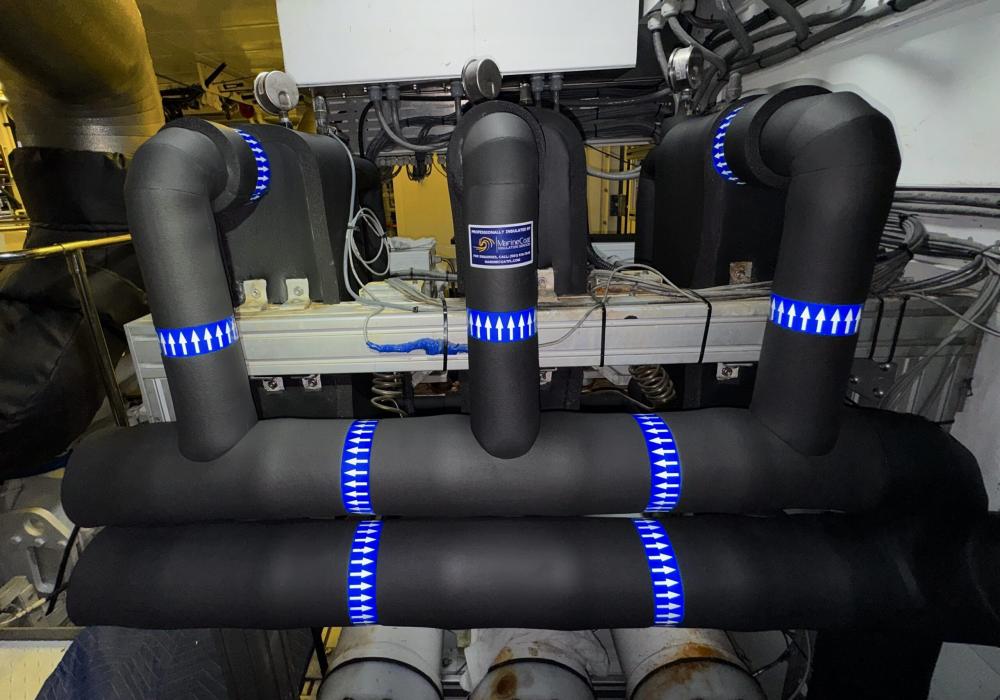

A few times, defining the project scope is the initial step in planning. Marine insulation projects involve extensive assessments of ship layouts, piping networks, and environmental conditions below deck. Marine insulation companies begin by identifying areas where marine pipe insulation is critical, evaluating pipe sizes, fluid types, and operating temperatures. Detailed surveys help determine insulation thickness, material selection, and potential acoustic or thermal challenges. A comprehensive understanding of the scope prevents overlooked areas and ensures that all requirements, from fire safety to noise reduction, are integrated into the project plan.

Work Breakdown Structure for Efficient Execution

A few times, implementing a Work Breakdown Structure (WBS) proves indispensable. WBS allows teams to divide complex projects into manageable tasks and sub-tasks, assigning responsibilities clearly. For marine insulation companies, this approach ensures that each stage, from material procurement to insulation installation and inspection, is systematically addressed. By breaking down projects into smaller, achievable components, teams can monitor progress, adjust schedules, and allocate resources efficiently, reducing bottlenecks and ensuring quality standards for marine pipe insulation installations.

Gantt Charts and Scheduling Techniques

A few times, visual scheduling tools like Gantt charts are crucial for coordinating tasks across multiple teams. Marine insulation projects often involve simultaneous operations in different areas of the ship, and Gantt charts allow project managers to sequence tasks, monitor dependencies, and identify potential delays. Marine insulation companies rely on these charts to ensure that marine pipe insulation installation aligns with other shipboard activities, minimizing disruption to operations. Real-time schedule tracking ensures that deadlines are met without sacrificing quality or safety.

Resource Allocation and Risk Management

A few times, careful allocation of resources is a hallmark of professional marine insulation planning. Skilled companies analyze labor availability, equipment needs, and material requirements to avoid shortages or delays. For marine pipe insulation, this may include specialized tools, insulation wraps, and fire-resistant coatings. Risk management strategies are integrated alongside resource planning, identifying potential hazards such as pipe corrosion, high-vibration areas, or tight installation spaces. Proactive mitigation measures reduce downtime and prevent costly rework, enhancing overall project efficiency.

Quality Assurance and Inspection Protocols

A few times, project planning in marine insulation emphasizes quality assurance protocols. Marine insulation companies develop detailed inspection schedules to verify that marine pipe insulation meets thermal, acoustic, and safety standards. Periodic checks during installation detect inconsistencies, compression gaps, or alignment issues that could compromise performance. Integrating quality control into the project plan ensures that insulation systems provide optimal functionality and longevity, while also satisfying regulatory compliance and shipowner expectations.

Collaboration and Communication Strategies

A few times, effective communication is critical for marine insulation projects. Teams often work in confined shipboard environments where coordination between engineers, installers, and safety officers is essential. Marine insulation companies implement collaborative planning techniques, including daily briefings, progress reports, and shared documentation platforms. Clear communication prevents misunderstandings, streamlines decision-making, and ensures that each team member understands their role in the installation of marine pipe insulation.

Leveraging Technology in Project Planning

A few times, advanced digital tools support project planning efforts. Software solutions for project scheduling, resource management, and 3D modeling allow marine insulation companies to simulate pipe layouts and predict potential installation challenges. Virtual planning reduces errors, enhances material utilization, and improves the precision of marine pipe insulation placement. Digital models can also be shared with clients, offering transparency and enabling faster approval processes.

Sustainability and Compliance Integration

A few times, sustainability considerations are integrated into project planning. Many marine insulation companies now prioritize eco-friendly insulation materials and processes that meet international environmental standards. This includes selecting low-VOC, recyclable insulation products for marine pipe insulation and ensuring energy-efficient installation practices. By combining compliance with environmental stewardship, companies deliver projects that are both high-performing and responsible.

Ultimately, project planning techniques employed by marine insulation companies are the backbone of successful marine pipe insulation installations. From initial scope definition and WBS implementation to risk management, quality assurance, and sustainable practices, each stage ensures optimal performance and safety. Once executed meticulously, these strategies guarantee efficient, durable, and high-quality insulation outcomes that enhance vessel comfort and operational reliability.