Industrial Screening Reimagined: The Role of Vibrating Screen Vibration Motor

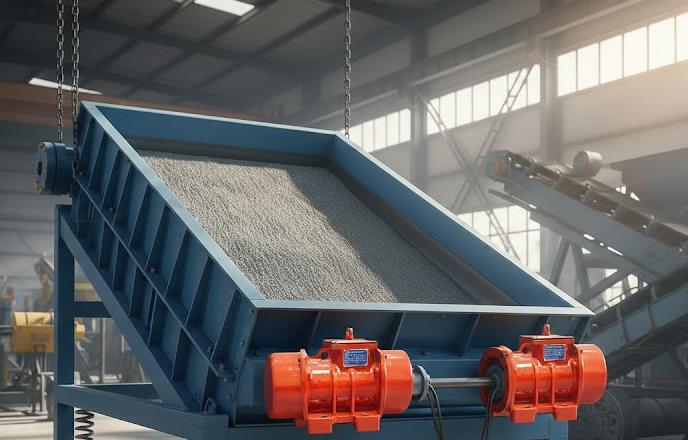

In modern bulk material handling and mineral processing, the vibrating screen is not merely a piece of equipment—it is a productivity gatekeeper. At the core of its performance lies a critical component that is often underestimated but never replaceable: the vibration motor. Choosing the right vibrating screen vibration motor manufacturer directly determines screening efficiency, operational stability, energy consumption, and lifecycle cost.

1. Why the Vibration Motor Defines Vibrating Screen Performance

A vibrating screen relies on controlled excitation force to stratify, transport, and separate materials. Unlike conventional drive motors, vibration motors generate centrifugal force through eccentric blocks, converting rotational motion into linear, circular, or elliptical vibration.

Key performance parameters include:

-

Excitation force accuracy

-

Amplitude stability under load

-

Synchronization reliability (for dual-motor systems)

-

Thermal performance during continuous operation

A professional vibrating screen vibration motor manufacturer does not simply supply a motor—it engineers a vibration solution matched to screen size, material characteristics, and duty cycle.

2. Core Engineering Parameters That Truly Matter

2.1 Excitation Force vs. Screen Throughput

Excitation force must be precisely matched to:

-

Screen deck area

-

Material bulk density

-

Particle size distribution

-

Inclination angle

Over-excitation leads to:

-

Excessive bearing load

-

Structural fatigue

-

Increased noise and power loss

Under-excitation results in:

-

Poor stratification

-

Low screening efficiency

-

Material accumulation

Manufacturers like SUDA MOTOR design vibration motors with finely adjustable eccentric blocks, allowing users to tune excitation force without changing motor models.

2.2 Frequency Control and Vibration Consistency

Screening efficiency depends on vibration frequency remaining stable under fluctuating loads. Inferior motors often experience frequency drift due to:

-

Rotor imbalance

-

Weak shaft rigidity

-

Inconsistent electromagnetic design

A qualified vibrating screen vibration motor manufacturer ensures:

-

High rotor dynamic balance grade

-

Rigid shaft and bearing system

-

Stable electromagnetic torque output

This stability is critical in mining, metallurgy, and aggregate processing where material load varies constantly.

3. Structural Design: Built for Harsh Industrial Environments

Vibration motors operate in some of the most demanding environments:

-

Dust-intensive conditions

-

High humidity

-

Elevated temperatures

-

Continuous 24/7 operation

Professional manufacturers focus on:

-

High-strength cast or ductile iron housings

-

IP65–IP66 protection levels

-

Heavy-duty bearings with extended lubrication cycles

-

Optimized heat dissipation paths

SUDA MOTOR incorporates reinforced housings and industrial-grade insulation systems, ensuring stable operation in mining, coal, chemical, and cement industries.

4. Single-Motor vs. Dual-Motor Configurations

A competent vibrating screen vibration motor manufacturer supports multiple system architectures:

-

Single-Motor Systems

-

Circular vibration

-

Compact structure

-

Suitable for light to medium screening tasks

-

Dual-Motor Systems

-

Linear vibration

-

Higher screening accuracy

-

Ideal for large-scale, high-capacity screens

Synchronization accuracy in dual-motor systems is non-negotiable. Any phase deviation causes uneven vibration, accelerated wear, and screen damage. Manufacturers with deep application experience, such as SUDA MOTOR, design motors specifically optimized for synchronized operation.

5. Energy Efficiency and Lifecycle Cost Considerations

Initial purchase price represents only a fraction of total ownership cost. Long-term factors include:

-

Power consumption

-

Bearing replacement frequency

-

Downtime losses

-

Maintenance labor

A reliable vibrating screen vibration motor manufacturer optimizes:

-

Electromagnetic efficiency

-

Mechanical transmission efficiency

-

Thermal stability to reduce insulation aging

High-efficiency vibration motors from SUDA MOTOR help operators reduce energy consumption while extending service intervals—an increasingly important advantage under global energy cost pressures.

6. Customization Capability: A Key Manufacturer Differentiator

No two screening applications are identical. Leading manufacturers provide:

-

Custom excitation force ranges

-

Special voltage and frequency options

-

Explosion-proof designs

-

High-temperature or corrosion-resistant configurations

As an experienced vibration motor supplier, SUDA MOTOR supports OEM customization, allowing seamless integration into diverse vibrating screen designs across global markets.

7. Application Scenarios That Demand Manufacturer Expertise

A professional vibrating screen vibration motor manufacturer must understand real-world applications, including:

-

Mining and quarrying – high load, abrasive materials

-

Coal processing – continuous operation, dust resistance

-

Chemical industry – corrosion protection

-

Food and pharmaceutical screening – hygiene and precision

-

Metallurgy and recycling – impact resistance and reliability

Application knowledge directly influences motor selection, mounting orientation, and long-term performance.

8. Why Manufacturer Selection Matters More Than Ever

In a competitive industrial environment, equipment reliability is not optional. Choosing a proven vibrating screen vibration motor manufacturer ensures:

-

Predictable screening performance

-

Lower total cost of ownership

-

Reduced unplanned downtime

-

Long-term supply and technical support

With its focus on engineering precision, industrial durability, and application-driven design, SUDA MOTOR has become a trusted partner for vibrating screen manufacturers and end-users worldwide.

Conclusion

A vibrating screen is only as effective as the vibration motor driving it. Beyond basic specifications, true performance comes from engineering depth, manufacturing quality, and application understanding. Selecting the right vibrating screen vibration motor manufacturer is therefore a strategic decision—one that directly impacts productivity, efficiency, and operational stability.

Manufacturers like SUDA MOTOR exemplify how vibration motor technology, when engineered correctly, becomes a powerful enabler of modern screening systems rather than a hidden bottleneck.