The Future of Automation: Why Soft Gripper Technology Is Transforming Modern Manufacturing

In today’s rapidly advancing industrial landscape, manufacturers are under constant pressure to increase efficiency, maintain product quality, and handle a wider variety of goods than ever before. Traditional rigid robotic systems, while powerful, often struggle with delicate, irregular, or unpredictable items. This is where the rise of Soft Gripper technology is making a revolutionary impact. With flexible, adaptive, and highly precise gripping mechanisms, soft robotics is reshaping how industries—from food processing to electronics—approach automation.

Among the innovators in this field, SRT Soft Gripper stands out as a business bringing advanced capabilities to companies seeking next-level handling solutions. But what makes soft robotic gripping systems so valuable, and why are businesses worldwide shifting toward this technology?

The Rise of Soft Robotics

Soft robotics is no longer an emerging trend—it’s becoming a mainstream requirement in modern automation. Companies such as Soft Robotics Inc have paved the way by proving that flexible, adaptive robots can outperform traditional machinery in specific applications. The core advantage comes from the ability of Soft Grippers to mimic the gentle, versatile motions of the human hand.

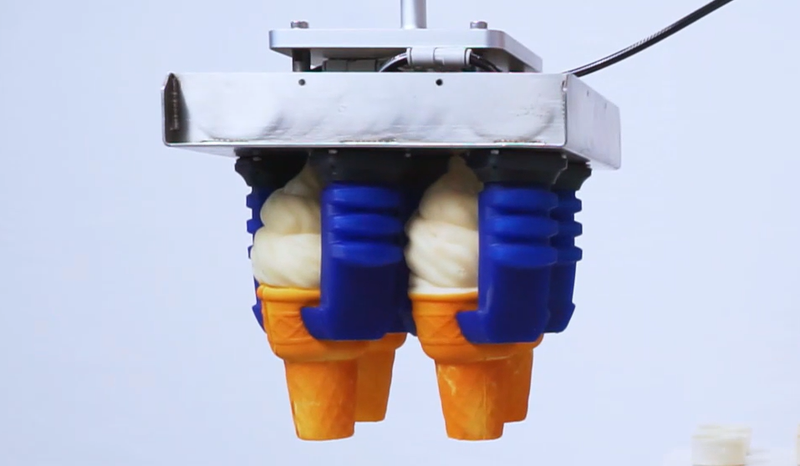

Instead of rigid metal components, these systems utilize compliant materials such as silicone, elastomers, and pneumatic structures. This allows a Soft Robot Gripper to grasp a wide variety of products without causing damage, making them ideal for industries handling fragile or easily deformed items.

Why Industries Prefer Soft Grippers

1. Versatility in Handling

Products vary widely in shape, texture, and delicacy. Conventional grippers require precise programming and often need to be changed when switching product types. In contrast, Soft Grippers automatically conform to the shape of an object, reducing downtime and improving operational flexibility.

2. Reduced Damage and Waste

Many manufacturing lines deal with delicate goods—fruits, bakery items, small electronics, pharmaceuticals, and more. The gentle touch of a Soft Robot Gripper minimizes breakage and product loss, leading to higher yield and better customer satisfaction.

3. Simplified Integration

Soft robotic systems are designed to integrate seamlessly with existing robotics platforms. They require less force control, reduced programming complexity, and lower risk of machinery-related accidents.

4. Improved Safety

Since soft robotic components are made from compliant materials, they pose significantly less risk to human workers. This is especially valuable in collaborative environments where robots and humans work side by side.

The Role of a Soft Robotics Solutions Supplier

As demand for adaptive automation grows, finding a knowledgeable Soft Robotics Solutions Supplier is crucial. Businesses need guidance not only on selecting the right gripper but also on configuring it for specific processes, products, and environments. A reliable supplier provides:

-

Expert consultation

-

Custom gripping configurations

-

Ongoing technical support

-

Integration assistance across various robotics platforms

This level of partnership ensures that companies can maximize the return on their investment in soft robotics.

Choosing the Best Soft Gripper Manufacturer

With the increase in options on the market, selecting the Best Soft Gripper Manufacturer becomes a strategic decision. Top manufacturers must offer:

-

Durable, food-safe materials

-

High-performance gripping force with gentle handling

-

Customizable designs

-

Compatibility with leading robotics systems

-

Proven success across multiple industries

Manufacturers who meet these criteria help businesses automate processes that were previously too delicate or complex for rigid robotics.

How SRT Soft Gripper Leads in Soft Robotic Innovation

The solutions offered by SRT Soft Gripper exemplify the next level of performance in soft robotics. Designed to handle a wide range of product shapes and sizes, their systems excel in industries such as food processing, packaging, logistics, and pharmaceuticals. Their approach focuses on improving reliability while maintaining the gentle precision that soft robotics is known for.

With cutting-edge engineering and customer-centric design, SRT delivers grippers that adapt quickly to changes in product lines—an essential capability for today’s fast-moving production environments.

A Look Toward the Future of Automation

The acceleration of automation is just beginning, and technologies like Soft Gripper systems are setting the stage for more intelligent, adaptable, and human-friendly robotics. As flexible automation becomes a necessity rather than a luxury, companies will increasingly rely on innovators and suppliers who can deliver advanced robotic solutions.

Whether handling fragile produce, precise electronic components, or irregularly shaped consumer goods, the power of soft robotics is undeniable. Solutions powered by Soft Robotics Inc, supported by trusted suppliers, and advanced by manufacturers at the forefront of the industry are transforming what is possible on production lines worldwide.

Soft robotics represents not just a technological upgrade, but a shift toward smarter, safer, and more efficient automation—making now the perfect time for businesses to embrace the soft robotic revolution.