Bonded for a Greener Tomorrow: Epoxy Resins in Alternative Fuel Storage

Alternative fuel adoption depends heavily on safe, efficient, and lightweight storage solutions. Epoxy resin-based composite pressure vessels are meeting this need by offering strength, corrosion resistance, and longevity for hydrogen, CNG, and biogas applications.

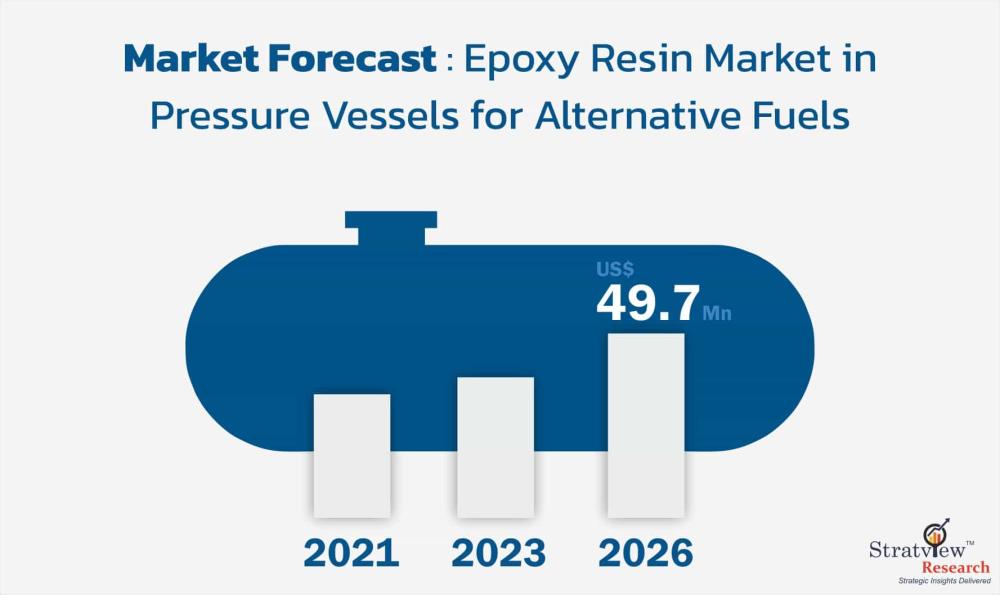

According to Stratview Research, the epoxy resin market in pressure vessels for alternative fuels is likely to grow at a healthy CAGR of 16.9% during 2021-2026 to reach USD 49.7 million in 2026.

Request a sample report to preview our in-depth analysis.

https://stratviewresearch.com/Request-Sample/192/epoxy-resin-market-in-pressure-vessels.html#form

Drivers

- Rising Hydrogen Mobility: Demand from automotive and rail sectors.

- Safety-Driven Regulations: Strict performance testing for fuel storage systems.

- Operational Efficiency: Lightweight vessels reducing fuel consumption.

- Public Funding: Subsidies for clean fuel infrastructure.

Challenges

- Market Volatility: Fluctuating raw material prices.

- Skilled Workforce Requirements: Need for specialized manufacturing expertise.

- Technology Adoption Rate: Slow uptake in regions with limited infrastructure.

Trends

- Low-Density Epoxy Systems: Weight reduction without strength loss.

- Automation in Winding: Consistency and quality control in vessel production.

- Coatings & Liners: Epoxy-compatible barrier layers for improved fuel containment.

Opportunities

- Defense Sector: Lightweight tanks for mobile energy systems.

- Remote Community Power: Renewable gas storage for off-grid locations.

- Industrial Backup Systems: Energy storage for critical infrastructure.

Conclusion

Epoxy resins are a key enabler in the growth of alternative fuel storage markets. With continued advances, they will support global decarbonization goals while meeting performance and safety standards.